PCA9685 16-Channel 12-bit PWM/Servo Driver

View on Amazon

Overview

About PCA9685 16-Channel 12-bit PWM/Servo Driver

The PCA9685 is a powerful 16-channel PWM driver, ideal for controlling servos, LEDs, and other PWM-based devices. It communicates via I²C, making it easy to integrate with ESP32, Arduino, and Raspberry Pi.

⚡ Key Features

- 16 Independent PWM Channels – Control multiple servos or LEDs simultaneously.

- High-Resolution PWM – 12-bit resolution (4096 steps) for precise control.

- Adjustable PWM Frequency – Ranges from 24 Hz to 1526 Hz.

- Wide Voltage Compatibility – Logic voltage: 2.3V – 5.5V; separate V+ pin for 5V–6V external power.

- Expandable I²C Addressing – Connect up to 62 PCA9685 modules on the same I²C bus.

Thanks to its scalability and precision, the PCA9685 is perfect for robotics, automation, and advanced lighting systems requiring synchronized motion or lighting effects. 🚀

Get Your PCA9685

💡 Prices are subject to change. We earn from qualifying purchases as an Amazon Associate.

PCA9685 Specifications

Complete technical specification details for PCA9685 16-Channel 12-bit PWM/Servo Driver

📊 Technical Parameters

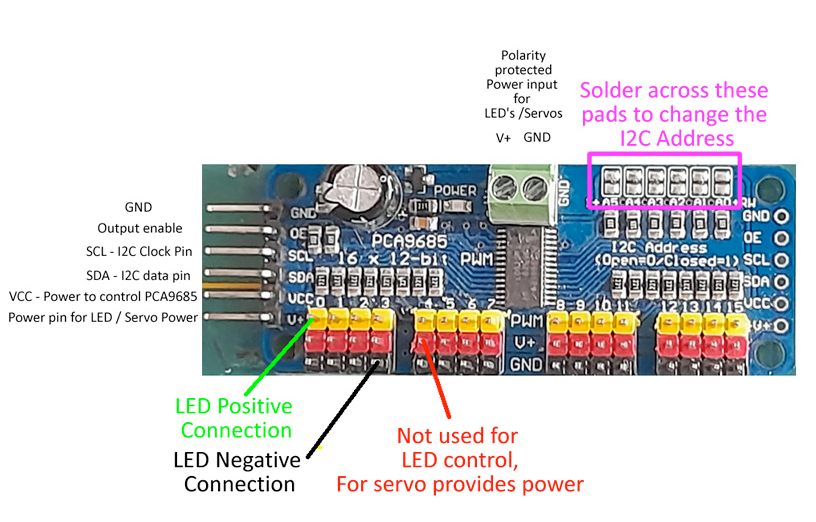

PCA9685 Pinout

The PCA9685 has multiple pins for I²C communication, external power, and 16 PWM output channels.

Visual Pinout Diagram

Pin Types

Quick Tips

address: 0x40 (default), configurable via A0-A5 solder pads,PWM resolution: 12-bit (4096 steps)

frequency: 24 Hz to 1526 Hz (adjustable),16 independent PWM channels

to 62 modules can share same I²C bus,External V+ required for servos and high-current LEDs

Pin Descriptions

| Pin Name | Type | Description | Notes |

|---|---|---|---|

1 VCC | Power | Logic power supply (2.3V-5.5V). Connect to 3.3V or 5V. | Powers the I²C logic and PWM circuitry. |

2 GND | Power | Ground connection. Connect to microcontroller and power supply ground. | Common ground for all devices. |

3 SDA | I2C | I²C Serial Data line. Bidirectional data communication. | Connect to ESP32 GPIO 21 (default SDA). |

4 SCL | I2C | I²C Serial Clock line. Clock signal for I²C communication. | Connect to ESP32 GPIO 22 (default SCL). |

5 V+ | Power | External power for servos/LEDs (5V-6V). Separate from VCC logic power. | Required for high-current devices. Use regulated power supply. |

6 Outputs 0-15 | PWM | 16 independent PWM output channels. Each generates 12-bit (4096 steps) PWM signals. | Connect to servo signal wires, LED anodes, or other PWM devices. |

7 OE | Control | Output Enable (active low). Pull low to disable all PWM outputs. | Optional - usually left unconnected or pulled high. |

8 ADR (A0-A5) | Address | I²C address selection pins. Solder bridges to set custom address. | Default address: 0x40. Can address up to 62 modules (0x40-0x7F). |

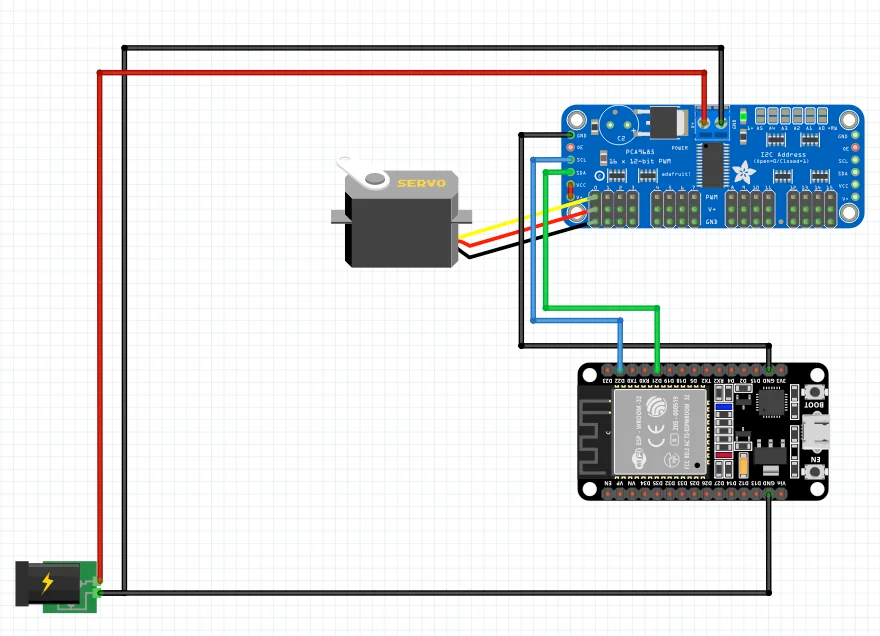

Wiring PCA9685 to ESP32

To interface the PCA9685 with an ESP32, connect VCC to 3.3V or 5V, GND to ground, SDA to GPIO 21, SCL to GPIO 22, and V+ to an external 5-6V power supply for servos/LEDs.

Visual Wiring Diagram

Connection Status

Protocol

Pin Connections

| PCA9685 Pin | Connection | ESP32 Pin | Description |

|---|---|---|---|

1 VCC Required | 3.3V or 5V | Logic power supply. Use 3.3V or 5V depending on your setup. | |

2 GND Required | GND | Ground connection. Must be common with ESP32 and external power. | |

3 SDA Required | GPIO 21 | I²C data line. Use pull-up resistors (4.7kΩ recommended). | |

4 SCL Required | GPIO 22 | I²C clock line. Use pull-up resistors (4.7kΩ recommended). | |

5 V+ Required | External 5-6V Supply | External power for servos/LEDs. Do NOT use ESP32 5V pin for multiple devices. | |

6 OE Optional | Optional GPIO | Output enable control. Pull low to disable all outputs. |

pull-up resistors (4.7kΩ) required on SDA and SCL lines

I²C address: 0x40 (can be changed via address pins)

Object]

all grounds together: ESP32, PCA9685, and external power supply

470µF-1000µF capacitor across V+ and GND to stabilize power

frequency for servos: 50Hz (standard)

current per channel: 25mA (total board: 400mA)

up to 62 PCA9685 boards on same I²C bus

Frequently Asked Questions about PCA9685

What is the PCA9685 used for?

What voltage does the PCA9685 support?

What is the PCA9685 PWM frequency range?

How many devices can be connected to one I²C bus?

PCA9685 Troubleshooting

Common issues and solutions to help you get your sensor working

Common Issues

Issue: Servos connected to the PCA9685 do not move as expected or exhibit erratic behavior.

Possible causes include insufficient power supply, incorrect wiring, or improper PWM signal configuration.

Solution: Ensure that the servos receive adequate power, as they can draw significant current, especially during startup. Use a separate, stable power supply for the servos, and connect the grounds of the PCA9685, microcontroller, and power supply together to establish a common reference. Verify that the PWM frequency is set appropriately for servo operation, typically around 50 Hz.

Issue: The PCA9685 module is not recognized on the I2C bus, leading to communication failures.

Possible causes include incorrect I2C address configuration, faulty wiring, or issues with the microcontroller's I2C interface.

Solution: Use an I2C scanner sketch to detect the PCA9685's address, which defaults to 0x40 but can be changed by adjusting the address pins. Ensure that the SDA and SCL lines are correctly connected and that pull-up resistors are present if required by your setup. Confirm that no other devices on the I2C bus share the same address, as this can cause conflicts.

Issue: LEDs connected to the PCA9685 do not light up or respond to PWM signals.

Possible causes include incorrect wiring, improper LED configuration (common anode vs. common cathode), or incorrect PWM settings.

Solution: Verify that LEDs are connected with the correct polarity and that the PCA9685's output mode matches the LED configuration. For common anode LEDs, ensure that the outputs are sinking current, and for common cathode LEDs, that they are sourcing current. Adjust the PWM duty cycle settings in your code to control the LED brightness appropriately.

Issue: The PCA9685 module becomes excessively hot during operation.

Possible causes include excessive current draw from connected devices, inadequate power supply, or short circuits.

Solution: Ensure that the total current draw of all connected devices does not exceed the PCA9685's specifications. Use appropriate current-limiting resistors for LEDs and verify that servos or motors are within the current limits. Check for any wiring mistakes that could cause short circuits, and provide adequate ventilation to dissipate heat.

Debugging Tips

Use the Serial Monitor to check for error messages and verify the sensor's output. Add debug prints in your code to track the sensor's state.

Use a multimeter to verify voltage levels and check for continuity in your connections. Ensure the power supply is stable and within the sensor's requirements.

Additional Resources

PCA9685 Programming Examples

Ready-to-use code examples for different platforms and frameworks

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Create a PCA9685 object

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

// Define the servo parameters

#define SERVOMIN 150 // Minimum pulse length count

#define SERVOMAX 600 // Maximum pulse length count

#define SERVO_FREQ 50 // Analog servos run at ~50 Hz

void setup() {

Serial.begin(115200);

pwm.begin();

pwm.setPWMFreq(SERVO_FREQ); // Set PWM frequency to 50 Hz

}

void loop() {

// Sweep the servo back and forth

for (int pulselen = SERVOMIN; pulselen <= SERVOMAX; pulselen++) {

pwm.setPWM(0, 0, pulselen); // Channel 0 controls the servo

delay(10);

}

for (int pulselen = SERVOMAX; pulselen >= SERVOMIN; pulselen--) {

pwm.setPWM(0, 0, pulselen);

delay(10);

}

}#include <stdio.h>

#include "driver/i2c.h"

#include "esp_log.h"

// PCA9685 I2C address and parameters

#define I2C_MASTER_NUM I2C_NUM_0

#define I2C_MASTER_SDA_IO 21

#define I2C_MASTER_SCL_IO 22

#define I2C_MASTER_FREQ_HZ 100000

#define PCA9685_ADDR 0x40

#define PCA9685_MODE1 0x00

#define PCA9685_PRESCALE 0xFE

#define SERVO_MIN 150

#define SERVO_MAX 600

#define CHANNEL_0 0

static const char *TAG = "PCA9685_SERVO";

void i2c_master_init() {

i2c_config_t conf = {

.mode = I2C_MODE_MASTER,

.sda_io_num = I2C_MASTER_SDA_IO,

.sda_pullup_en = GPIO_PULLUP_ENABLE,

.scl_io_num = I2C_MASTER_SCL_IO,

.scl_pullup_en = GPIO_PULLUP_ENABLE,

.master.clk_speed = I2C_MASTER_FREQ_HZ,

};

i2c_param_config(I2C_MASTER_NUM, &conf);

i2c_driver_install(I2C_MASTER_NUM, conf.mode, 0, 0, 0);

}

void pca9685_write_byte(uint8_t reg, uint8_t data) {

uint8_t write_buf[2] = {reg, data};

i2c_master_write_to_device(I2C_MASTER_NUM, PCA9685_ADDR, write_buf, 2, 1000 / portTICK_PERIOD_MS);

}

void pca9685_set_pwm(uint8_t channel, uint16_t on, uint16_t off) {

uint8_t write_buf[5] = {

0x06 + 4 * channel, // LEDn_ON_L register address

on & 0xFF, // Low byte of ON value

on >> 8, // High byte of ON value

off & 0xFF, // Low byte of OFF value

off >> 8 // High byte of OFF value

};

i2c_master_write_to_device(I2C_MASTER_NUM, PCA9685_ADDR, write_buf, 5, 1000 / portTICK_PERIOD_MS);

}

void pca9685_init() {

pca9685_write_byte(PCA9685_MODE1, 0x10); // Put PCA9685 into sleep mode

uint8_t prescale = (uint8_t)(25000000 / (4096 * 50) - 1); // Set PWM frequency to 50 Hz

pca9685_write_byte(PCA9685_PRESCALE, prescale);

pca9685_write_byte(PCA9685_MODE1, 0xA0); // Restart and set to normal mode

}

void app_main() {

ESP_LOGI(TAG, "Initializing I2C...");

i2c_master_init();

ESP_LOGI(TAG, "Initializing PCA9685...");

pca9685_init();

while (1) {

// Sweep the servo from minimum to maximum

for (int pulse = SERVO_MIN; pulse <= SERVO_MAX; pulse++) {

pca9685_set_pwm(CHANNEL_0, 0, pulse);

vTaskDelay(10 / portTICK_PERIOD_MS);

}

// Sweep the servo back from maximum to minimum

for (int pulse = SERVO_MAX; pulse >= SERVO_MIN; pulse--) {

pca9685_set_pwm(CHANNEL_0, 0, pulse);

vTaskDelay(10 / portTICK_PERIOD_MS);

}

}

}This ESP-IDF code demonstrates how to control a servo motor using the PCA9685 PWM driver module. The i2c_master_init function initializes the ESP32's I2C interface for communication with the PCA9685. The pca9685_init function sets up the PWM frequency to 50 Hz, ideal for controlling servos. The pca9685_set_pwm function sends PWM signals to a specific channel, determining the servo position based on pulse width. In the app_main function, the servo is swept back and forth by incrementally adjusting the pulse length between SERVO_MIN and SERVO_MAX on channel 0.

pca9685:

- id: pca9685_hub1

frequency: 500

output:

- platform: pca9685

pca9685_id: 'pca9685_hub1'

channel: 0This configuration sets up a PCA9685 PWM driver in ESPHome. The pca9685 section defines a hub with an ID pca9685_hub1 and a frequency of 500 Hz. The output section specifies a single output channel (channel 0) controlled by the PCA9685 hub. This is useful for controlling devices like servos or LEDs. For more details, visit ESPHome PCA9685 Output Documentation.

platformio.ini

[env:esp32dev]

platform = espressif32

board = esp32dev

framework = arduino

lib_deps =

adafruit/Adafruit PWM Servo Driver Library @ ^2.4.0

wire

build_flags =

-D CONFIG_I2C_MASTER_SDA=21

-D CONFIG_I2C_MASTER_SCL=22

monitor_speed = 115200main.cpp

#include <Wire.h>

#include "Adafruit_PWMServoDriver.h"

// Create PCA9685 object

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

// Define servo parameters

#define SERVOMIN 150 // Minimum pulse length count

#define SERVOMAX 600 // Maximum pulse length count

#define SERVO_FREQ 50 // Servo frequency (50 Hz)

void setup() {

Serial.begin(115200); // Initialize serial communication

Serial.println("Initializing PCA9685...");

pwm.begin(); // Initialize PCA9685

pwm.setPWMFreq(SERVO_FREQ); // Set PWM frequency to 50 Hz

}

void loop() {

// Sweep the servo from minimum to maximum

for (int pulselen = SERVOMIN; pulselen <= SERVOMAX; pulselen++) {

pwm.setPWM(0, 0, pulselen); // Channel 0

delay(10);

}

// Sweep the servo back from maximum to minimum

for (int pulselen = SERVOMAX; pulselen >= SERVOMIN; pulselen--) {

pwm.setPWM(0, 0, pulselen); // Channel 0

delay(10);

}

}This code controls a servo motor using the PCA9685 module with an ESP32. The Adafruit_PWMServoDriver library is used to communicate with the PCA9685 over I2C. The setup function initializes the PCA9685 and sets the PWM frequency to 50 Hz, suitable for most servos. In the loop, the servo motor connected to channel 0 is swept back and forth by varying the pulse length between SERVOMIN (150) and SERVOMAX (600), which define the servo's angular range. The pwm.setPWM function sends these pulse values to the PCA9685 to control the servo position.

from machine import Pin, I2C

from time import sleep

from pca9685 import PCA9685

# Initialize I2C

i2c = I2C(0, scl=Pin(22), sda=Pin(21), freq=100000)

# Initialize PCA9685

pwm = PCA9685(i2c)

pwm.freq(50) # Set frequency to 50 Hz for servos

# Servo pulse range

SERVOMIN = 150 # Minimum pulse length

SERVOMAX = 600 # Maximum pulse length

def set_servo_angle(channel, angle):

"""Convert angle (0-180) to pulse length and set PWM."""

pulse = SERVOMIN + int((SERVOMAX - SERVOMIN) * angle / 180)

pwm.channels[channel].duty_u16(pulse)

try:

while True:

# Sweep servo from 0 to 180 degrees

for angle in range(0, 181, 1):

set_servoThis MicroPython code demonstrates how to control a servo motor using the PCA9685 module. The PCA9685 library is used to communicate with the module over I2C, where pins 22 (SCL) and 21 (SDA) are configured. The pwm.freq(50) sets the PWM frequency to 50 Hz, which is required for controlling servo motors. The set_servo_angle function calculates the appropriate pulse length for a given angle (0-180 degrees) and sends it to a specified channel. In the loop, the servo sweeps back and forth by incrementing and decrementing the angle, controlling the servo's position. The try block allows stopping the program gracefully using a keyboard interrupt.

Wrapping Up PCA9685

The ESP32 PCA9685 16-Channel 12-bit PWM/Servo Driver is a powerful servo sensor that offers excellent performance and reliability. With support for multiple development platforms including Arduino, ESP-IDF, ESPHome, PlatformIO, and MicroPython, it's a versatile choice for your IoT projects.

Best Practices

For optimal performance, ensure proper wiring and follow the recommended configuration for your chosen development platform.

Safety First

Always verify power supply requirements and pin connections before powering up your project to avoid potential damage.

Ready to Start Building?

Now that you have all the information you need, it's time to integrate the PCA9685 into your ESP32 project and bring your ideas to life!

Explore Alternative Sensors

Looking for alternatives to the PCA9685? Check out these similar sensors that might fit your project needs.

MG996R Servo

The MG996R is a high-torque servo motor ideal for robotics and demanding DIY projects. Operating on 4.8V to 7.2V, it delivers up to 11 kg·cm...

SG90 Mini Servo

The SG90 is a compact micro servo motor ideal for robotics and DIY projects. Operating on 4.8V to 6V, it delivers 1.8 kg·cm torque, with a...

MG90S Mini Servo

The MG90S is a robust micro servo motor designed for robotics and DIY projects. Operating on 4.8V to 6V, it provides up to 2.2 kg·cm torque,...